Umhlahlandlela wokusebenza obaluleke kakhulu we-4 wezinkuni zokubhoboza izinkuni nokucaciswa okuthandwa kakhulu kwe-HW drill drill nangokusebenzisa izimbobo zokubhola kanye nama-hinges bits kumathuluzi wezinkuni ezimboni.

1: Khetha izivivinyo ezifanele futhi wenze ukuvikelwa

1.1 I-drill bit yenzelwe imishini yokubhola yobuciko bokhuni. Naka ukuqondiswa kokujikeleza kwe-bit drill. Sidinga ukukhetha inkomba eyodwa ukusuka kwesokudla noma kwesokunxele.

1.2 Kufanele sigweme ukusika izinto ezingezona ezokhuni ezifana nezinsimbi, isihlabathi namatshe.Ngenxa yokuthi izingcezu zokubhoboza izinkuni zisetshenziselwa ukuthola izimbobo ezijwayelekile nezibushelelezi zangaphakathi zamabhodi ahlukahlukene ahlanganisiwe nokhuni oluqinile, hhayi ngezinto ezinzima kakhulu.

1.3 Sebenzisa izivivinyo zobude obujwayelekile ngangokunokwenzeka, bese ucindezela izingodo uzibambe ngesikhathi sokusebenza ukuze uvikele imikhiqizo esetshenzisiwe engafanelekile noma ukusonteka kwalezi zindawo zokuzivivinya zethoshi ngokungaboni noma ngomgodi.

1.4 Kuyadingeka futhi ukusebenzisa ijakhethi ejwayelekile. Umgodi wangaphakathi ogqokiwe noma oqoshiwe uzoholela ekubambeni kwamandla okwanele okuzokwenza ukuthi ibhilidi lokubhola liphume futhi lidlidlize, okuholele kwimikhiqizo engafanelekile.

1.5 Hlola futhi uqiniseke ukuthi ucingo lwaphansi lusekelwe ngokuqinile, ingxenye ngayinye ijwayelekile, indawo yokusebenza ikhanya, (abasebenzi abangaqeqeshiwe abasebenzisi ithuluzi lakhe lomshini).

2. Gqoka izingubo eziqinile, okhalweni nemikhono evulekile, ungafaki uthayi, ubucwebe, ungawafaki amagilavu, unake ukuvikela amehlo.

2. Ukugcinwa kokhuni lokubhoboza izinkuni

2.1. Uma usebenzisa i-drill, yikhiphe ebhokisini bese uyifaka ku-collet chuck yesipina noma umagazini wethuluzi wokushintshwa kwe-othomathikhi okuzenzakalelayo. Kubuyisele ebhokisini ngemuva kokusetshenziswa.

2.2 Ukukala ububanzi bensimbi yokubhoboza izinkuni ezimbonini, sebenzisa ithuluzi lokulinganisa elingathintwa njengemicroscope yethuluzi ukuvimbela uhlangothi olusika ekuxhumaneni nethuluzi lokulinganisa lomshini futhi lilimale.

2.3 Eminye imishini ye-CNC router isebenzisa izindandatho zokubeka. Eminye imishini ye-CNC yokumba ayisebenzisi izindandatho zokubeka. Uma kusetshenziswa izindandatho zesikhundla, ukujula ngesikhathi sokufakwa kufanele kube kunembile. Uma izindandatho zokubeka zingasetshenziswanga, ukunwebeka kwebhayela lokuphotha othini lokuphotha kufanele kube nenembile. Ukuze wenze ukulungisa okufanayo, imishini yokubhoboza izinkuni enama-eksisi amaningi kufanele igcine ukujula okufanayo kokuphotha kontambo ngamunye. Uma kungahambelani, kungadala ukuthi isibhilidi sokubhola sifike etafuleni noma sehluleke ukubhoboza ipuleti, okuholele ekumoshweni nasekudweni kwepuleti lokhuni.

2.4. Ngezikhathi ezijwayelekile, kungasetshenziswa imicroscope yesitiriyo engu-40x ukubheka ukugqokwa komkhawulo wokusika kwalezi zinsimbi zethambo nangokubhoboza izimbobo zemigodi ngamathiphu e-carbide.

2.5. Njalo hlola ukugxila kwe-chuck namandla okubamba we-chuck. Ukugxila okungampofu kuzodala ukuthi kubhidlizwe ama-drill amancane. Uma umfutho wokuminyanisa ungemuhle, isivinini sangempela sizohluka kunesivinini esibekiwe futhi izingcezu zokubhoboza izinkuni zizoshelela kusuka kuma-chucks.

2.6 Njalo hlola unyawo lokucindezela lokuphotha. Indawo yokuxhumana yonyawo lokucindezela kufanele ibe nendawo evundlile futhi ime mpo kushaft enkulu ngaphandle kokunyakaza ukuze kuvinjelwe ukuzivivinya kwethoshi kungaphuli futhi kuphambuke izimbobo kulokho kubhola.

2.7 Ukuqinisekisa impilo yensiza ye-woodworking drill yakho nokunciphisa ukwehluleka, kufanele sihlole njalo ukuthi uwoyela wokuthambisa ku-drill wezinkuni wenele noma cha. Uma kushoda, sicela uyigcwalise ngesikhathi.

2.8 Ngesikhathi sokulungiswa kwalezi zimboni zezinkuni zokumba izinkuni, sicela uqiniseke ukuthi unqamule ugesi ngaphambi kokulungisa amaphutha nokuwagcina ukuze uvikele izingozi. Wonke amatshe e-sawdust adaluliwe, uthuli, imfucumfucu, njll. Kubhola lokwenza izinkuni kufanele kususwe nsuku zonke. Ukunakekelwa kwansuku zonke kufanele kukhokhwe ekususeni uthuli lwenkuni nothuli kojantshi besiqondisi, izihlalo ezishelelayo nojantshi bomhlahlandlela webhokisi eliqondile, futhi ojantshi besiqondisi kufanele bahlanzwe futhi bathanjiswe ngaphambi kokuhamba njalo. Hlola izinga lamafutha lalezi zingxenye ezimbili nsuku zonke.

2.9 Bheka ukuthi umfutho womoya ocindezelweyo uyahlangabezana yini nezinga elijwayelekile, ingcindezi ejwayelekile ingu-0.5-0.8mpa; hlola ukuthi amanzi esihlungi emajoyintini amabili ayadedelwa noma cha. Hlola ukuthi umshini wokucindezela umoya kagesi wezindawo zokuzivivinya zethoshi nokubhola izimbobo ungaphakathi kwebanga lenani elicacisiwe, sicela uhlole nokuthi ngabe kukhona yini ukuvuza komoya ekuhlanganyeleni kohlelo lwendlela yegesi bese uthatha izinyathelo ezifanele.

3: Isitayela 4 ethandwa kakhulu sokuzivivinya kancane ngokhuni CNC imishini yomzila

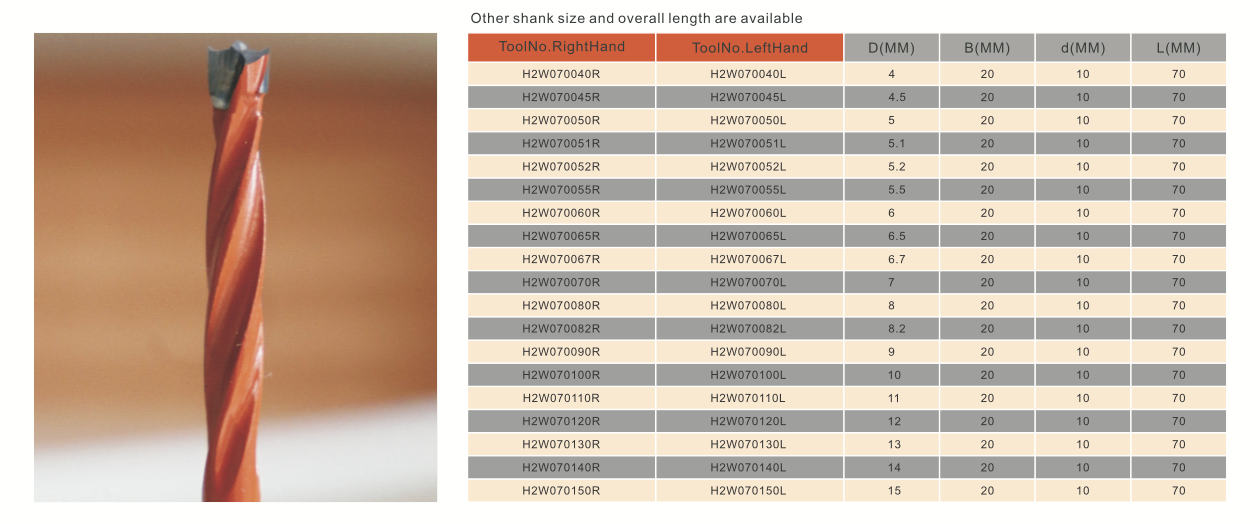

3.1 HW Brad point boring bings (dowel drill) enezinkuni eziqinile, iPhaneli elenziwe ngokhuni le-MDF, izinhlanganisela zezinkuni, izinto zepulasitiki nezinto ezinamathele.

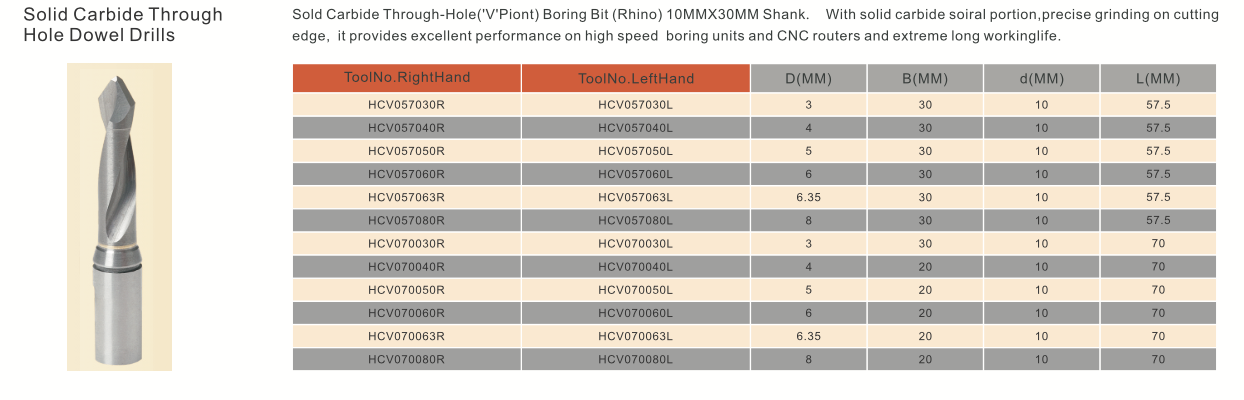

3.2 HW Ngokusebenzisa izimbobo zokumba izimbobo zokhuni oluqinile, i-MDF, njll.

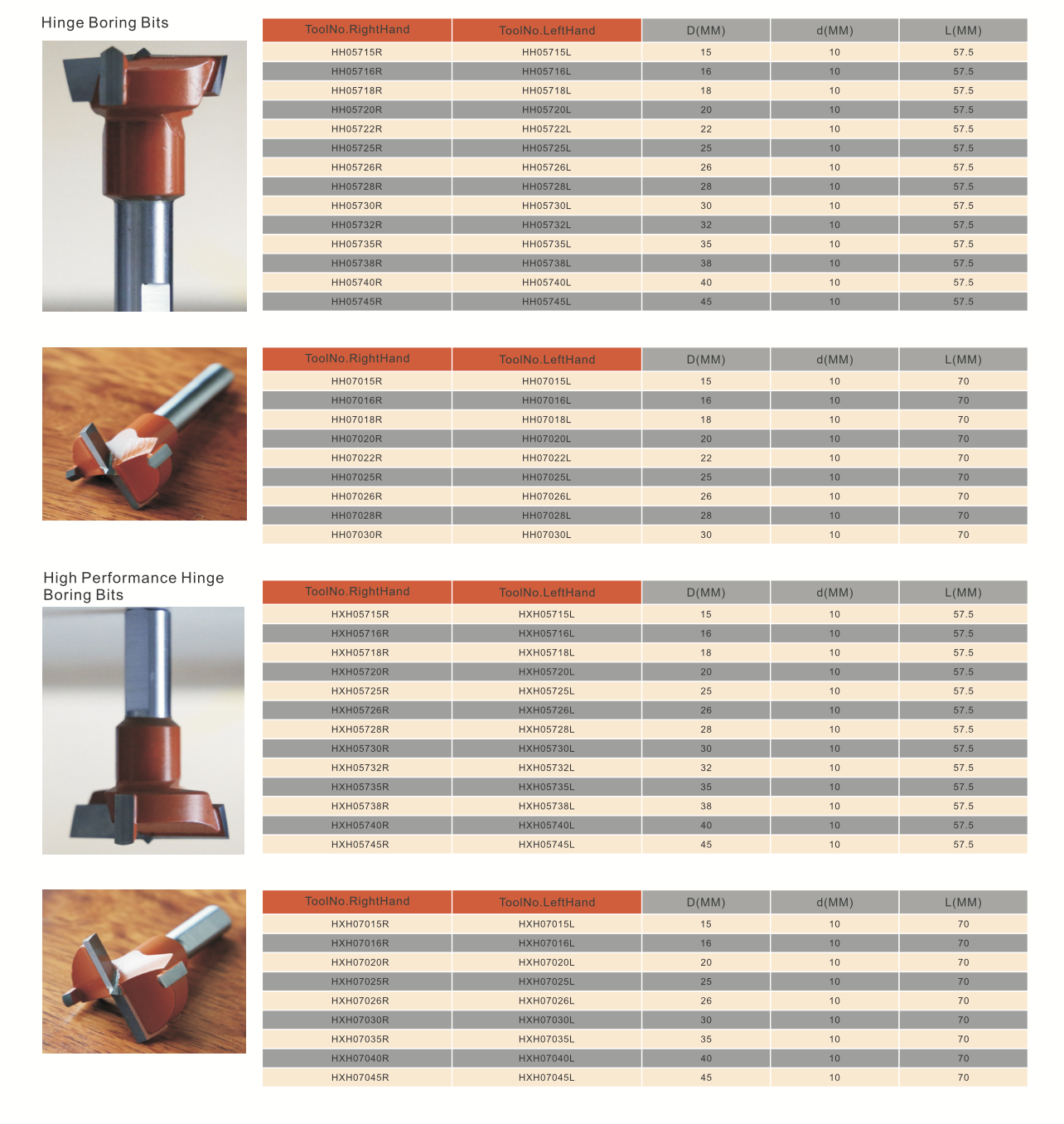

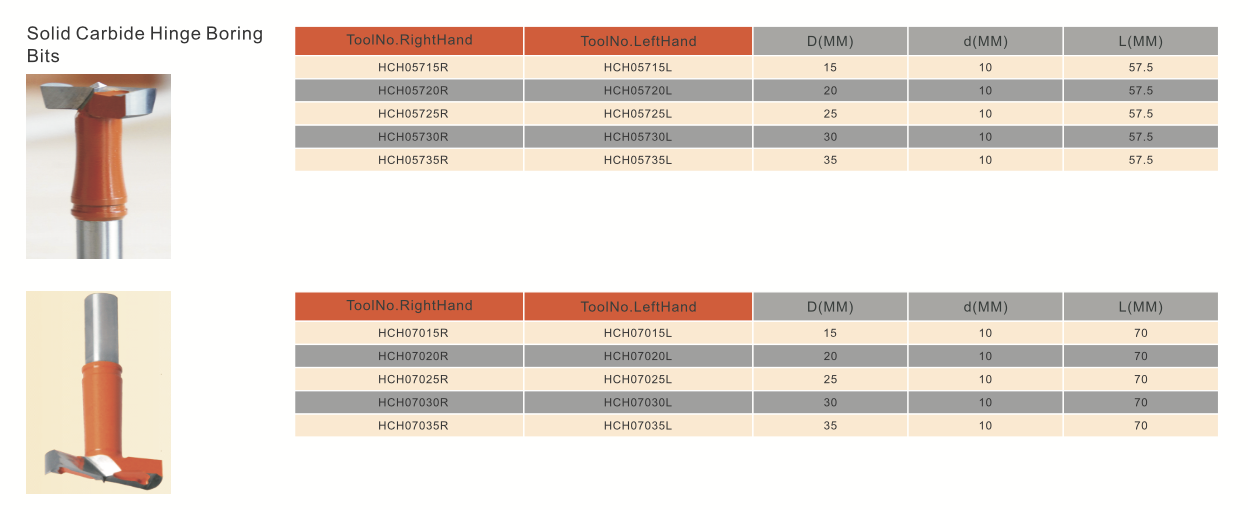

3.3 Izindonga ze-hinge eziyisicefe

3.4 Carbide router bits for wood solid, MDF, njll.

4: Izinkinga nezixazululo zezinkinga zivame ukwenzeka ekusetshenzisweni kwezingcezu zokubhoboza izinkuni

4.1 Broken Edge ngenkathi machining

Isizathu: (1) Umphumela wamaphuzu awusacijile.

(2) Iphoyinti lendawo ephakathi nendawo nokugxila kwe-shank kufakazelwe ngokweqile.

(3) umshini wokushintshana we-shaft shaft umshini omkhulu.

(4) Izibopho ze-shank zikhululekile futhi azikhiyiwe.

(5) Ipulangwe lihamba ngenkathi kubhola ngaphansi komzila we-CNC.

(6) Isivinini sokuzungeza se-axis esiyinhloko asikwazi ukufana nesivinini sokudla sokuzivivinya kwezinkuni.

4.2 Umgodi uyisigaxa ngemuva kokulungiswa.

Isizathu: (1) Indawo yendawo yesikhungo sokubhola kwethoshi nokubhola izimbobo ayisacijile.

(2) Ipulangwe lihamba ngenkathi kusetshenzwa

(3) Isivinini sokuzungeza se-axis esiyinhloko asikwazi ukufanisa isivinini sokudla.

Umgodi wePlank uyashiswa ngemuva kokulungiswa.

Isizathu: (1) umgodi wokuvunguza uvinjiwe okuholela ekususweni okubi kwe-chip.

(2) Izinto ezenziwe ngomshini njengepulangwe, ukhuni alomile ngokwanele.

(3) Isivinini se-axis esiyinhloko asikwazi ukufanisa ijubane lokuphakela lawa ma-drill we-dowel, noma ngokusebenzisa izimbobo zemigodi.

Isixazululo: Lungisa umshini nemingcele yokusika, shintshela amathuluzi amasha

Ngaphansi kwezimo ezijwayelekile, izingcezu zokubhoboza izinkuni zingasebenza kahle kakhulu, kepha futhi kufanele futhi senze okusemandleni ukuthi singabhobozi esikhonkosini. Musa ukwenza ovundlile sokuprakthiza bit touch the mpo kancane bit ngephutha, ngaphandle kwalokho kancane sokuprakthiza izolimala. I-35mm hinge drill bit esetshenziselwe ihinji lomnyango idinga ukulungiswa kabusha ngokuvamile. Lapho uthenga ama-drill bits, siphakamisa ukuthi sithenge ezisezingeni eliphakeme, ukuze umsebenzi ube bushelelezi, futhi imikhiqizo eqediwe ibe mihle!

Umfutho womoya nawo ubaluleke kakhulu, kanjalo nesivinini sokuphakelayo. Ijubane le-drill bit bit futhi libhoboza izimbobo ngaphansi kwe-10mm / min lingashesha, kepha ibhithi engaphezulu kwe-15mm / min kumele ibe nesivinini sokudla okupholile, ngaphandle kwalokho izodabuleka kalula! Ukunakwa kufanele kunikezwe ekukhetheni kwamabhithi wokubhola. Jwayelekile izinga sokuzivivinya izingcezu zingasetshenziswa for MDF bebonke, izinga okusezingeni futhi esitebeleni Woodworking sokuprakthiza izingcezu basikisela kakhulu ukushefa ibhodi.

Isikhathi Iposi: Sep-15-2020