Isikhokelo sokusebenza esibaluleke kakhulu se-4 sokwenza izixhobo ze-woodworking kunye neenkcukacha ezithandwayo kakhulu ze-HW zokubhola kunye nokuqhekeza imingxunya kunye neehenjisi zezixhobo kwizixhobo zokusebenza kwokhuni.

1: Khetha uqheliso oluchanekileyo kwaye wenze ukhuseleko

1.1 I-drill bit yenzelwe i-rigs ye-woodworking rigs. Nikelani ingqalelo kwicala lokujikeleza bit drill. Kufuneka sikhethe icala elinye kwicala lasekunene okanye lasekhohlo.

1.2 Sifanele sikuphephe ukusika izinto ezingezizo iinkuni ezinjengezinyithi, isanti kunye namatye. Ngenxa yokuba izixhobo zokugrumba iinkuni zisetyenziselwa ukufumana imingxunya esemgangathweni kunye egudileyo yangaphakathi yeebhodi ezahlukeneyo kunye nemithi eqinileyo, hayi izinto ezinzima kakhulu.

1.3 Sebenzisa ukubhola okusemgangathweni ngokusemgangathweni kangangoko kunokwenzeka, kwaye ucinezele iinkuni ngokuqinileyo ngexesha lokusebenza ukunqanda iimveliso ezingasetyenziswanga okanye ukulungiswa kwezi drill zedowel ngokungaboni okanye ngomngxunya.

1.4 Kuyimfuneko ukusebenzisa ibhatyi esemgangathweni. Umngxunya ongaphakathi ogugileyo okanye otyhidiweyo uya kukhokelela ekungqinelaneni okwaneleyo okuya kubangela ukuba isuntsu lokubhabha liphaphazele lishukume, oko kukhokelele kwiimveliso ezingafanelekanga.

1.5 Jonga kwaye uqiniseke ukuba ucingo lomhlaba luzinzile, icandelo ngalinye liqhelekile, indawo yokusebenza iqaqambile, (abasebenzi abangaqeqeshwanga abasebenzisi isixhobo somatshini wakhe).

2. Nxiba iimpahla ezixineneyo, isinqe kunye nemikhono eqinileyo, akukho tie, akukho jewelry, akukho ziigloves, nikela ingqalelo ukukhusela amehlo.

2. Ulondolozo lwento yokusebenza kweenkuni

2.1. Xa usebenzisa i-drill, yikhuphe ebhokisini uze uyifake kwi-collet chuck ye-spindle okanye kwiphephancwadi yesixhobo sokutshintshwa ngokuzenzekelayo. Yibuyisele kwibhokisi emva kokusetyenziswa.

2.2 Ukulinganisa idayimani yesixhobo sokwenza umthi sokwenza imveliso, sebenzisa isixhobo sokulinganisa esingadibaniyo nesinjengemicroscope yokuthintela umda wokusika ekunxibelelaneni nesixhobo sokulinganisa ngomatshini kwaye wenzakale.

2.3 Abanye oomatshini be-CNC basebenzisa iiringi zokubeka. Abanye oomatshini be-CNC bokugrumba abazisebenzisi iiringi zokubeka. Ukuba kusetyenziswa amakhonkco obume, ubunzulu ngexesha lofakelo kufuneka buchaneke. Ukuba amakhonkco okubeka awasetyenziswanga, ubude be-drill kwi-spindle kufuneka buchaneke. Ukuze wenze uhlengahlengiso olufanayo, oomatshini be-axis abaninzi bokumba iinkuni kufuneka bagcine ubunzulu bokugrumba kwentsimbi nganye. Ukuba ayingqinelani, inokubangela ukuba isikroba sokugrumba sijikeleze itafile okanye sisilele ukugqobhoza ipleyiti, sikhokelele kwinkunkuma nakwizinto ezilahliweyo zepleyiti yomthi.

2.4. Ngamaxesha aqhelekileyo, imicroscope ye-stereo engama-40 ingasetyenziselwa ukukhangela ukunxiba komda wokusika wale drow drill kunye nasemngxunyeni wokugrumba umngxunya ngeengcebiso ze-carbide.

2.5. Ngalo lonke ixesha jonga ukugxila kwe-chuck kunye nokunyanzelwa kwe-chuck. Ukugxininiswa okungalunganga kuya kubangela ukuba kuqhekezwe i-diameter encinci kunye neendawo ezinkulu. Ukuba amandla nokubotshwa akulunganga, isantya eyiyo iya kwahluka isantya iseti kunye imithambo kusombiwa amasuntswana uya kutyibilika ukusuka chucks.

2.6 Soloko ujonga unyawo lokushicilela lokuphotha. Umphezulu woqhakamshelwano lonyawo lokucinezela kufuneka ube uthe tyaba kwaye ume nkqo kwishafti ephambili ngaphandle kokungcangcazela ukuthintela idowill ukuba ingaphuli kwaye iphambuke kwimingxunya yokomba.

2.7 Ukuqinisekisa ngobom benkonzo yakho yokubhola kunye nokunciphisa ukungaphumeleli, kufuneka sijonge rhoqo ukuba ioyile yokuthambisa kwi-drill ye-woodwork yanele na okanye hayi. Ukuba kukho ukunqongophala, nceda uyigcwalise ngexesha.

2.8 Ngexesha lokugcinwa kwezi zixhobo zokugrumba iinkuni, nceda uqiniseke ngokusika umbane ngaphambi kokulungisa kunye nokugcina ukuthintela iingozi. Yonke into ebunjiweyo, uthuli, ubutyobo, njl. Ingqwalaselo yemihla ngemihla kufuneka ihlawulwe ekususeni isarfust kunye nothuli kwiziporo zesikhokelo, izihlalo ezityibilikayo kunye nezikhokelo zomgaqo webhokisi ethe nkqo, kwaye iirayile zesikhokelo kufuneka zicocwe kwaye zithanjiswe ngaphambi kokuhamba ixesha ngalinye. Jonga inqanaba leoyile yamacandelo amabini yonke imihla.

2.9 Jonga ukuba uxinzelelo lomoya luxinene nomgangatho, uxinzelelo oluqhelekileyo yi-0.5-0.8mpa; jonga ukuba amanzi akwisihluzi kula malungu mabini akhutshiwe na okanye hayi. Jonga ukuba ngaba iswitshi yoxinzelelo lomoya wombane wedowuli kunye nokugqobhoza imingxunya kungaphakathi kuluhlu lwexabiso oluchaziweyo, nceda ujonge ukuba ngaba kukho ukuvuza komoya ngokudibeneyo kwenkqubo yendlela yegesi kwaye uthathe amanyathelo afanelekileyo.

3: I-4 ethandwa kakhulu isimbo sokubhola kancinane iinkuni kunye noomatshini CNC umzila

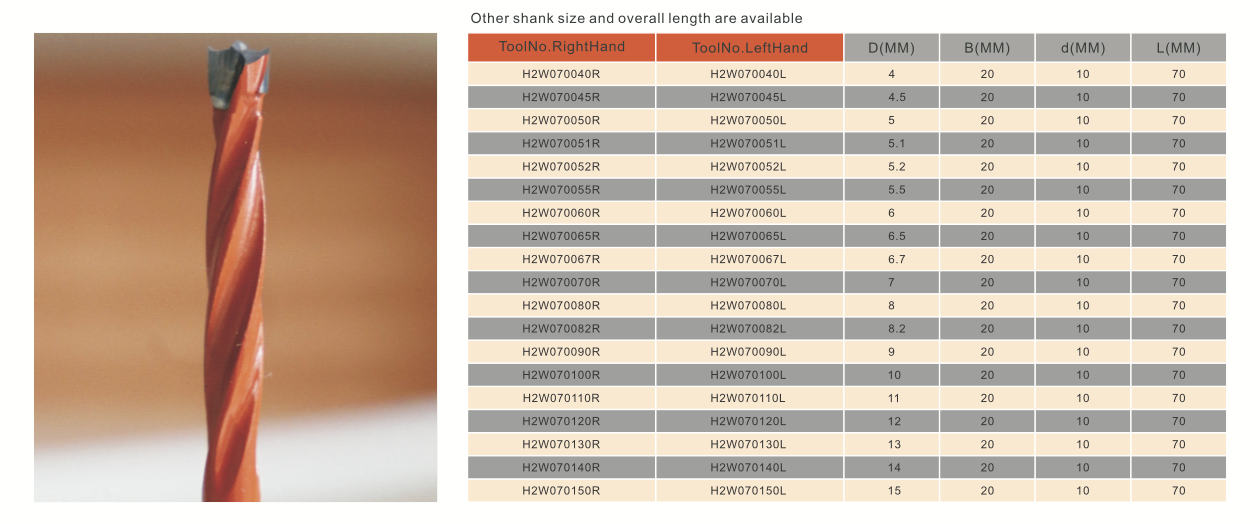

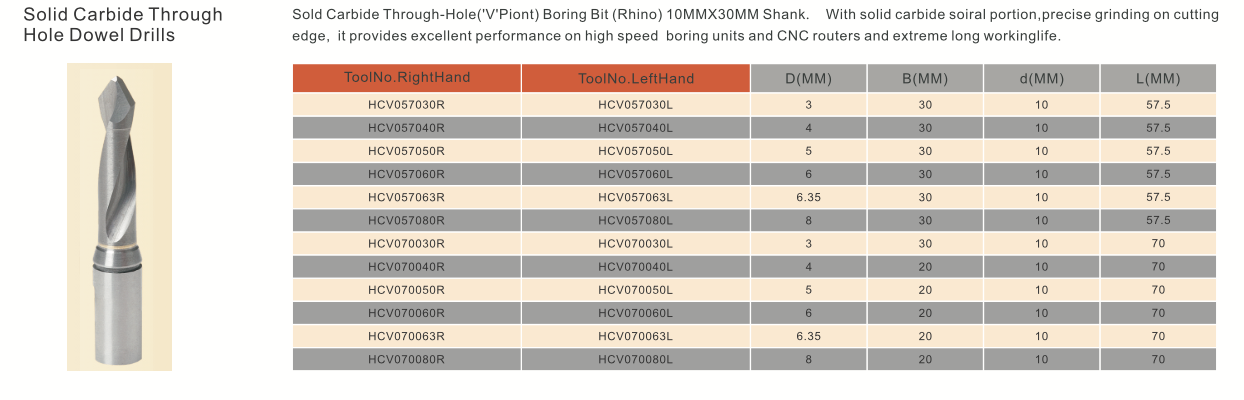

I-3.1 HW ye-Brad point boring boring (idowel drill) kunye neenkuni ezomeleleyo, iPhaneli esekwe kumthi ye-MDF, izinto ezenziwe ngomthi, iplastiki kunye nezinto ezenziwe ngomthi.

3.2 HW Ngokusebenzisa imingxunya yokomba imingxunya yeenkuni eziqinileyo, i-MDF, njl.

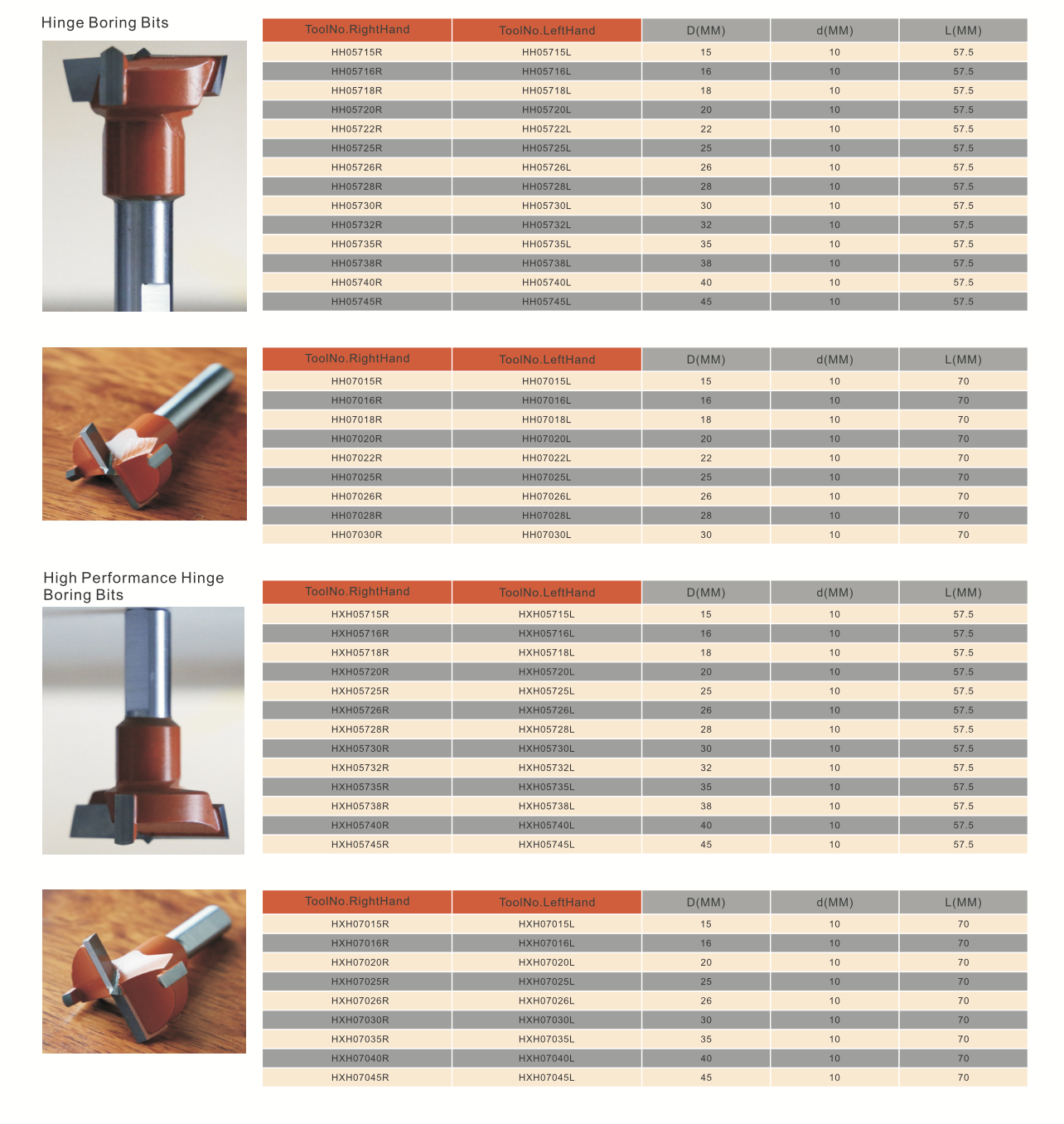

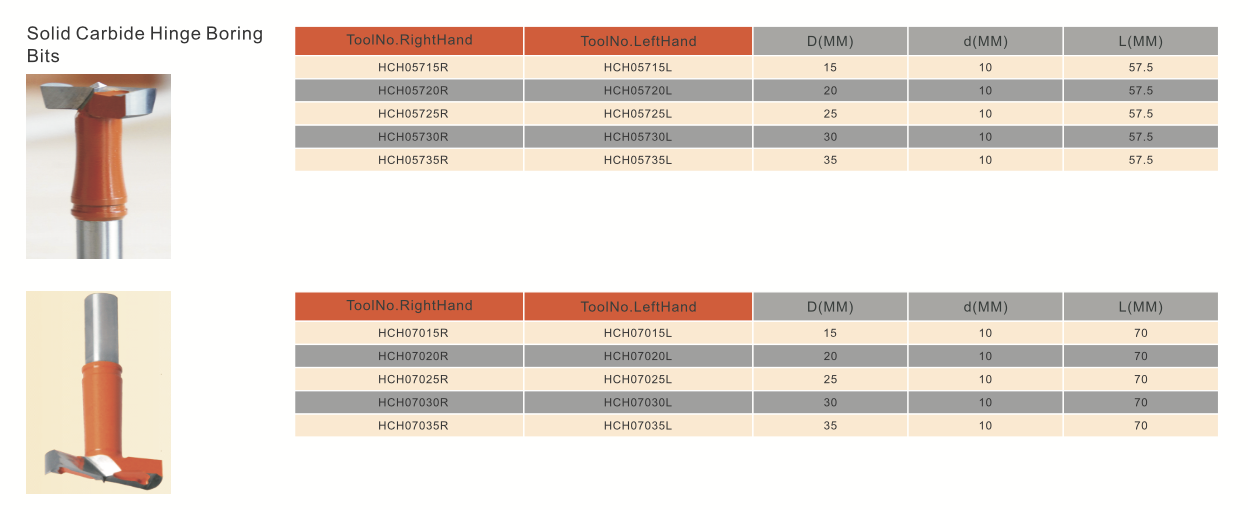

3.3 Iinjenge ezikruqulayo

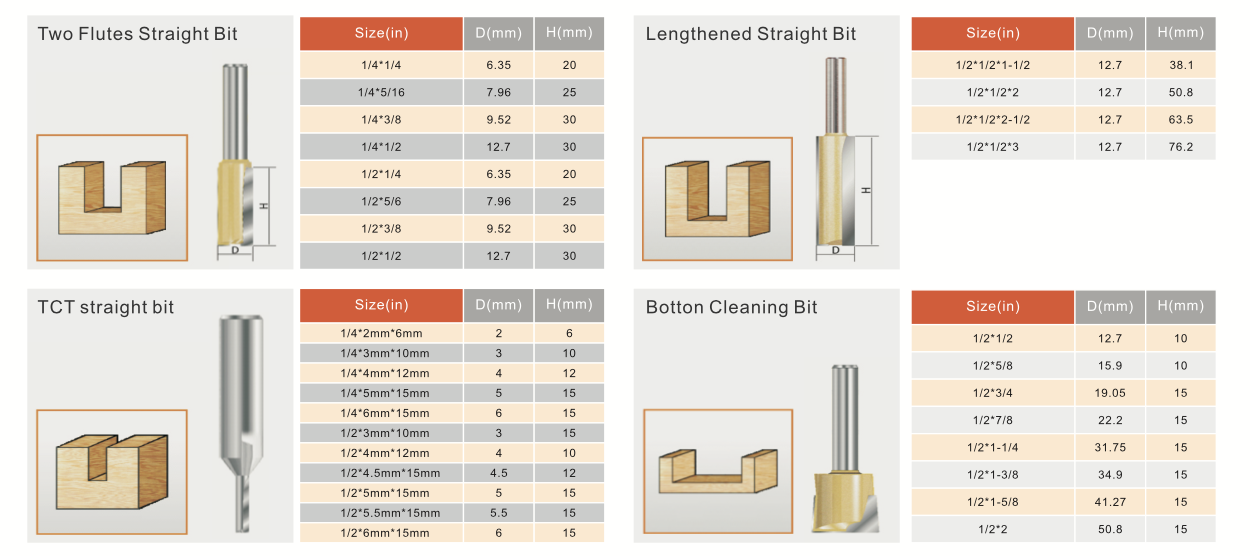

I-3.4 Carbide router bits for wood solid, MDF, njl.

I-4: Iingxaki kunye nezisombululo zeengxaki zihlala zisenzeka kusetyenziso lweebhola zokwenza izinto

4.1 I-Edge eyaphukileyo ngelixa kusenziwa umatshini

Isizathu: (1) Umda wamanqaku awusabukhali.

(2) Indawo yendawo embindini kunye nokugxilwa kwe-shank kuqinisekiswe ngaphezulu.

(3) i-CNC yomatshini wokujikeleza shaft ukubetha ngaphezulu.

(4) Izibopho ze-shank zikhululekile kwaye azitshixwanga.

(5) Iplanga lihamba ngelixa kusombiwa phantsi komzila we-CNC.

(6) Isantya sokujikeleza kwe-axis eyiNtloko asinakulingana nesantya sokondla i-drilling woodworking.

4.2 Umngxunya yi-ellipse emva koomatshini.

Isizathu: (1) indawo yendawo yeziko lokwemba idolo kunye nokugqobhoza umngxunya akusekho kubukhali.

(2) Iplank ihamba ngelixa kusenziwa umatshini

(3) Isantya sokujikeleza kwe-axis eyiNtloko asinakulingana nesantya sokondla.

Umngxuma wePlank utshisiwe emva koomatshini.

Isizathu: (1) indawo evaliweyo evaliweyo ekhokelela ekususweni kakubi kwe-chip.

(2) Izinto ezenziwe ngomatshini ezifana neplywood, iinkuni azomile ngokwaneleyo.

(3) Isantya sokujikeleza kwe-axis eyiNtloko ayinakulinganisa isantya sokondla kwezi zixhobo zokuqhuba, okanye ngokusebenzisa imingxunya yemingxunya.

Isisombululo: Lungisa umatshini kunye nokusika iiparameter, tshintsha izixhobo ezitsha

Phantsi kweemeko eziqhelekileyo, ukubhola iinkuni kusenokusebenza kakuhle kakhulu, kodwa kuya kufuneka sikwenze konke okusemandleni ukungabhobheli nzipho. Sukuyenza into ethe tyaba yokomba uthinte i-vertical drill ngempazamo, kungenjalo i-drill bit iya konakala. I-35mm hinge drill esetyenziselwa ihenjisi yomnyango kufuneka ihlaziywe rhoqo. Xa kuthengwa amasuntswana okumba, sicebisa ukuba sithenge ezikumgangatho ophezulu, ukuze umsebenzi ube mpuluswa, kwaye iimveliso ezigqityiweyo zilungile!

Uxinzelelo lomoya lukwabaluleke kakhulu, ngokunjalo nesantya sokondla. Isantya sedowuli yokugrumba kunye nokugqobhoza umngxunya ongaphantsi kwe-10mm / min sinokukhawuleza, kodwa isuntswana lokumba ngaphezulu kwe-15mm / min kufuneka libe nesantya sokutya kancinci, kungenjalo iya kugqabhuka ngokulula! Ingqalelo kufuneka ihlawulwe ekukhetheni kweebhola zokumba. Ngesiqhelo kusombiwa amasuntswana ezinokusetyenziselwa i-MDF ngokubanzi, umgangatho ophezulu kunye neebhithi ezizinzileyo zokumba izixhobo zicetyiswa ngamandla kwibhodi yokucheba.

Ixesha Post: Sep-15-2020