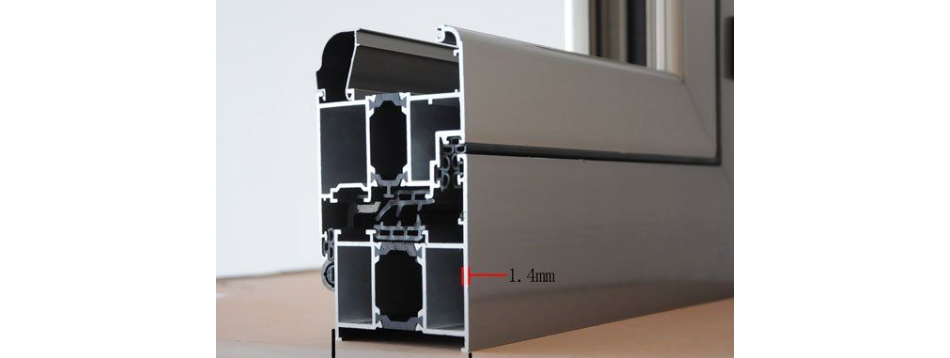

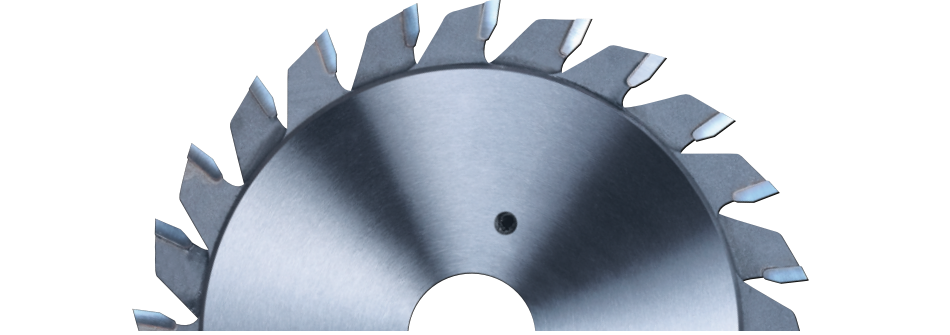

Iingxaki ezi-5 ezaziwa kakhulu kunye nezisombululo ekusebenziseni i-carbide yesetyhula yamacwecwe okusika iinkuni

Namhlanje siza kwabelana ngezinye zeengxaki ekuhlangatyezwane nazo ngexesha lokusetyenziswa kwe-carbide blade. Zeziphi izizathu eziphambili? Indlela yokujongana nazo?

Ingxaki yoku-1- Isandi esingaqhelekanga

Izizathu zezi zilandelayo:

1. I-alloy blade blade isetyenziswa gwenxa, iqondo lobushushu liphezulu kakhulu, kwaye isarha blade ikhubazekile ngenxa yamandla angaphandle. Ngeli xesha, ukulungiswa kuyafuneka kwaye kuyimfuneko.

2. Kukho izikhewu kwisixhobo sokuluka, ekubalekeni nasekujiweni.

3. Isetyhula carbide blade blade inento encanyathiselwe kuyo, kwaye ichukumisa izinto ezingaphandle kwezinto zokusika ngexesha lokusika.

4. Kuyacetyiswa ukuba uthenge i-alloy blade blade kunye neentambo ezingacuthwanga ukunciphisa ingxolo.

5. Isantya sokujikeleza asihambelani nemeko yokusika.

6. Isithuba esingaqhelekanga sokususa i-chip- jonga indawo leyo kwaye ulungelelanise indawo emi kuyo.

Ingxaki yesi-2-Kukho i-burrs okanye iindawo ezingalinganiyo kwindawo yokusebenza

Isixazululo: 1. Jonga ukuthambeka kwekhetshe yesarha yesetyhula, ibala lesarha elingalinganiyo kufuneka lilungisiwe

2. Isarha yesarha ebonwe ngezinyo inesiphene kwaye yonakele okanye ilumkise

3. Lungisa uze ulungise ufakelo lwesarha yesarha

4. Guqula isetyhula blade blade ukuba isarha blade isetyenziselwe ixesha elide kwaye ukuchaneka kwentloko yokusika akulunganga ngokwaneleyo ukusika.

5.Tshintsha enye indlela yamazinyo xa ufumanisa ukuba iprofayili yezinyo ayifanelekanga okanye inani lamazinyo lincinci (amazinyo e-BT aqhele ukusetyenziselwa iingcango kunye neefestile)

6. Lungisa ukuchaneka kwesixhobo sokuluka ukuba asichanekanga ngokwaneleyo.

7. Qiniseka ukuthambisa ajikeleze ngokwaneleyo.

Ingxaki yesi-3-ukondla ngokungaqhelekanga

Izizathu eziphambili zezi zilandelayo:

1. I-alloy saw blade slips

2. Intonga yokuluka incamathele kwezinye izinto.

3. Kukho ukuthintela kwizibuko lokukhutshwa.

Ingxaki yesine yokubanjwa kwe-carbide saw blade

Izizathu eziphambili zezi zilandelayo:

1. Imathiriyeli yesarha blade ayikulungelanga ukwenziwa kwezinto

2. Uyilo lwekhabhayithi yesetyhula yesarha yesangqa ayinangqondo kwaye iichips azinakususwa ngexesha

Ukusetyenziswa kakhulu kunye nobushushu obuphezulu besarha yesarha ngexesha lokulungiswa

4. Isetyhula blade blade ibanjiwe okanye umatshini othambisa uyaxhuma okanye isarha blade ifakwe ngokungachanekanga

Nceda umise umatshini kwangexesha ukuba le nto ingentla iyenzeka.

Ingxaki yesi-5-intloko yokusika ye-carbide yeesarha inxiba ngokukhawuleza okukhulu

Izizathu zezi: i-engile yomda wokusika ayinangqondo, ezinye iincakuba ezingaphantsi zinokunganyangeki kokunxiba okungaginyisi mathe, isarha yesarha ayixhomekekanga kubugcisa bokusebenza, kwaye isantya sebala lesarha siphezulu kakhulu.

Isixazululo: Jonga i-flange ye-spindle ukuze uqinisekise ukuma kwe-saw blade kunye nezixhobo, khangela isantya se-saw blade xa isebenza. Gaya kwaye ugcine isarade blade ngexesha. Ukuba oku kungasentla akunakusombululwa, nceda uzame isarha entsha.

Siyathemba kwaye siyakholelwa ukuba umgangatho ochanekileyo kunye nomgangatho ophezulu we-cemented carbide saw blade uya kuphucula umgangatho wemveliso, unciphise imijikelezo yokulungisa, kunye nokunciphisa iindleko zokuqhubekeka.

Ixesha Post: Sep-15-2020