Background: As woodworking cemented carbide tools are suitable for processing various wood-based panels and solid wood, the cutting effect is significantly better than that of high-speed steel tools, and they are increasingly used. Following woodworking carbide saw blades, woodworking cemented carbide dowel drill bits and hinge boring bits and woodworking cemented carbide routers are also gradually popularized.

Here is an introduction to which types of drill bits are suitable for hinge holes?

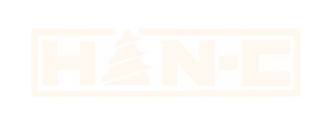

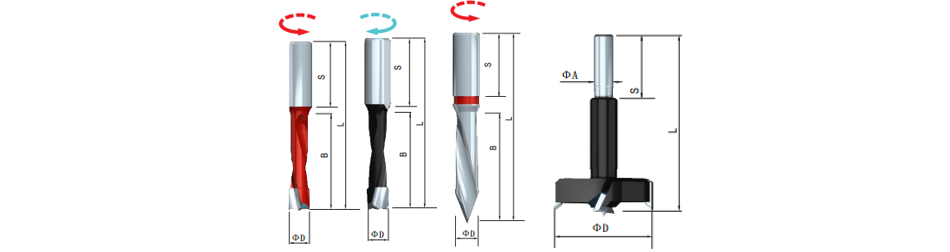

Hinge boring bits: The hinge drill is made to install the hinge. The hinge is generally a 35mm hole in the middle and 3mm holes on both sides. The hinge drill is also called a four-blade drill and is the same product. If a 35mm Right hand hinge boring bit is used in the middle, the 3mm hole on the side should use the opposite left hand and 3MMX57MM brad point boring bits and the direction of the drill and the main drill should be opposite, because the drilling equipment is designed like this.

The improper selection of the drill bit can cause edge bursting due to the following reasons:

1: The concentricity of the drill bit is not enough.

2: The gap between the drill bit and the drill sleeve is too large,

3: The hinge boring bits and dowel drill bits do not match the processing material or the veneer is too brittle. Another reason may be that the carbide bit is blunt.

If the drilling depth is too deep, it is easy to cause poor chip removal.

What are the maximum depth of drilling bits used for CNC woodworking of solid wood, MDF, artificial board?

| HW drill bits | Total Length | Dia | Max drilling depth |

| Dowel drill & through hole drill &Hinge boring bits | 57mm | 3mm-10mm | 20mm |

| 57mm | 11mm-14mm | 26mm | |

| 57mm | 15mm | 23mm | |

| 57mm | 15mm | 23mm | |

| 70mm | 3mm-10mm | 26mm | |

| 70mm | 11mm-14mm | 35mm | |

| 70mm | 15mm | 35mm |

Application of the drill bits: used for CNC or woodworking drilling rig of solid wood, MDF, artificial board, etc.

Advantages: The cutter head is made from super fine alloy, leading low-temperature welding technology to ensure tool life; data grinder ensures accuracy; various shaped cutting edge, unique scoring blade design, enhances the sharpness and strength of the drill point.

Next time we will introduce how to choose correct and proper dowel drill bits in different situation.

Post time: Sep-15-2020