4 most important operation guideline of woodworking drill bits and most popular specifications of HW dowel drills and through hole drills& hinges bits in industrial woodworking tools.

1: Choose correct drills and make protection

1.1 The drill bit is designed for professional woodworking drill rigs. Pay attention to the direction of rotation of the drill bit. We need to choose one direction from right hand or left hand.

1.2 We should avoid cutting non-wood materials such as metals, sand and stones.Because woodworking drill bits are used to get standard and smooth inner holes for various composite boards and solid wood, not for too hard materials.

1.3 Use standard length drills as much as possible, and press the wood tightly during operation to avoid unqualified processed products or deformation of these dowel drills for blind or through hole.

1.4 It is also necessary to use a standard jacket. Worn or tapered inner hole will leads to insufficient clamping force which will cause the drill bit to fly off and vibrate, resulting in unqualified products.

1.5 Check and make sure the ground wire is firmly grounded, each part is normal, the operating position is bright, (untrained personnel do not operate his machine tool).

2. Dress tight clothes, waist and tight sleeves, no tie, no jewelry, no gloves, pay attention to protect eyes.

2. Maintenance of woodworking drill bit

2.1. When using a drill, take it out of the box and install it into the collet chuck of the spindle or the tool magazine for automatic drill replacement. Put it back in the box after use.

2.2 To measure the diameter of the industrial woodworking drill bit, use a non-contact measuring instrument such as a tool microscope to prevent the cutting edge from contacting with the mechanical measuring instrument and being injured.

2.3 Some CNC router machines use positioning rings. Some CNC drilling machines do not use positioning rings. If position rings are used, the depth during installation must be accurate. If positioning rings are not used, the elongation of the drill bit on the spindle must be accurate. In order to make same adjustments, the multi-axis wood drilling machines should keep same drilling depth of each spindle. If it is not inconsistent, it may cause the drill bit to drill to the table or fail to drill through the plate, resulting in waste and scrap of the wood plate.

2.4. At ordinary times, a 40x stereo microscope can be used to check the wear of the cutting edge of these dowel drill and through hole drill bits with carbide tips.

2.5. Always check the concentricity of the chuck and the clamping force of the chuck. Poor concentricity will cause small-diameter drills to break and large apertures. If the clamping force is not good, the actual speed will be different from the set speed and the woodworking drills bits will slip from the chucks.

2.6 Always check the spindle presser foot. The contact surface of the presser foot should be horizontal and vertical to the main shaft without shaking to prevent the dowel drills from breaking and deviating holes in the drilling.

2.7 In order to ensure the service life of your woodworking drill and reduce failures, we must regularly check whether the lubricating oil on the woodworking drill is enough or not. If there is a shortage, please fill it in time.

2.8 During the maintenance of these industrial woodworking drill bits, please be sure to cut off the electrical power supply before debugging and maintaining to prevent accidents. All exposed sawdust, dust, debris, etc. on the woodworking drill should be removed daily. Daily attention should be paid to removing sawdust and dust on the guide rails, sliding seats and guide rails of the vertical box, and the guide rails should be cleaned and lubricated before moving each time. Check the oil level of the two parts daily.

2.9 Check whether the compressed air pressure meets the standard, the normal pressure is 0.5-0.8mpa; check whether the water in the filter in the two joints is discharged or not. Check whether the electric air pressure switch of the dowel drills and through hole drills bits is within the specified value range, please also check whether there is any air leakage in the joint of the gas path system and take appropriate measures.

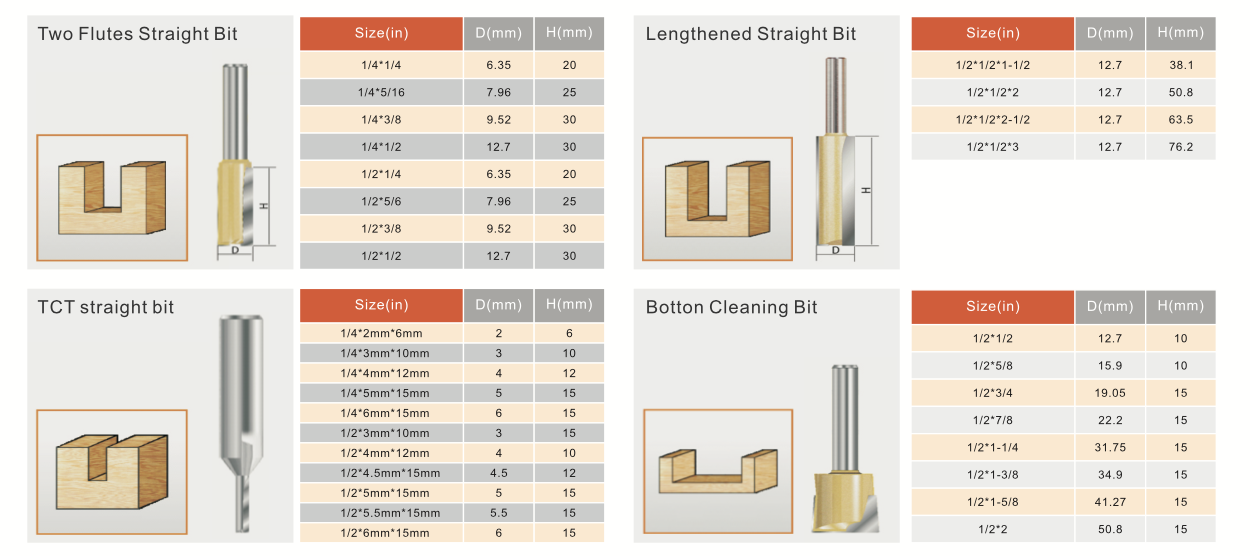

3: The 4 most popular style of drills bit for wood and CNC router machines

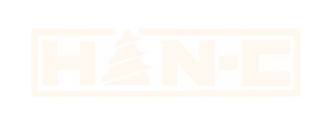

3.1 HW Brad point boring bits (dowel drills) with for solid wood, MDF wood-based Panel, wood composites, plastic and laminated materials.

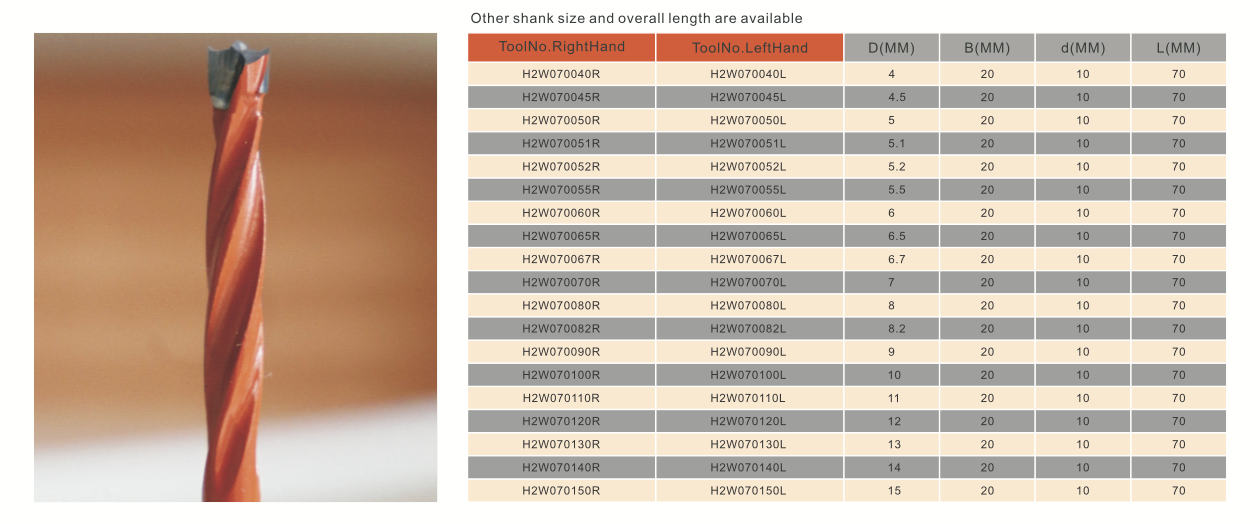

3.2 HW Through hole drill bits for solid wood, MDF, etc.

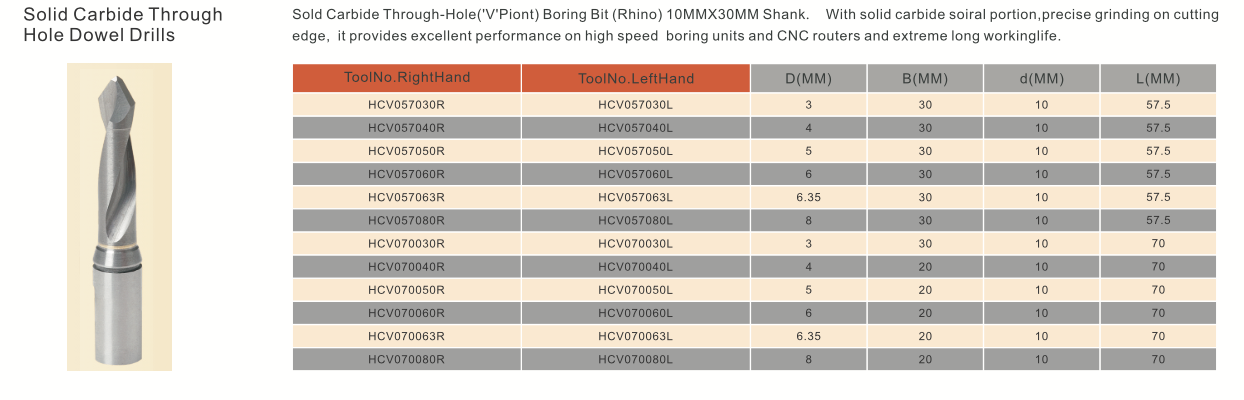

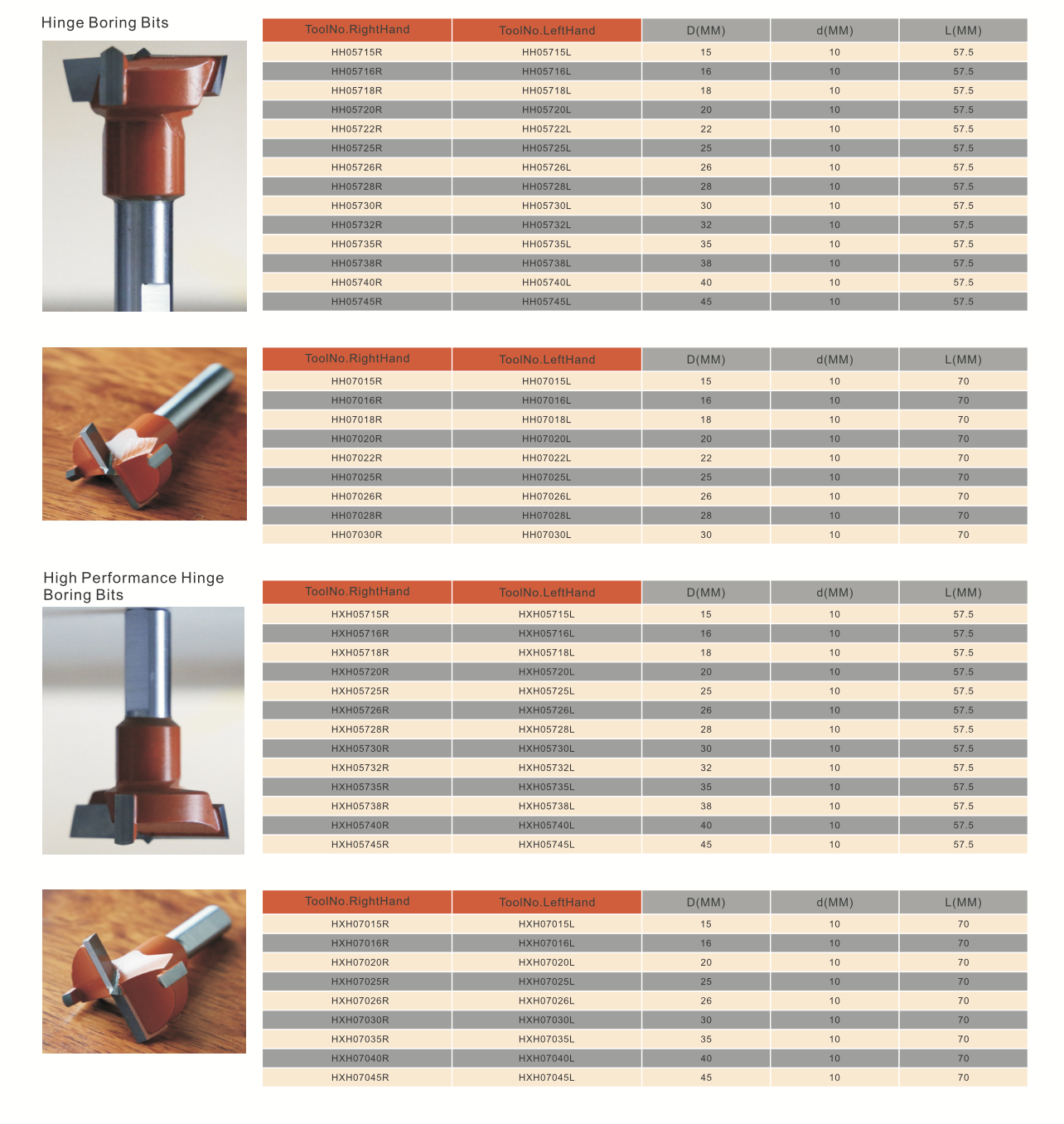

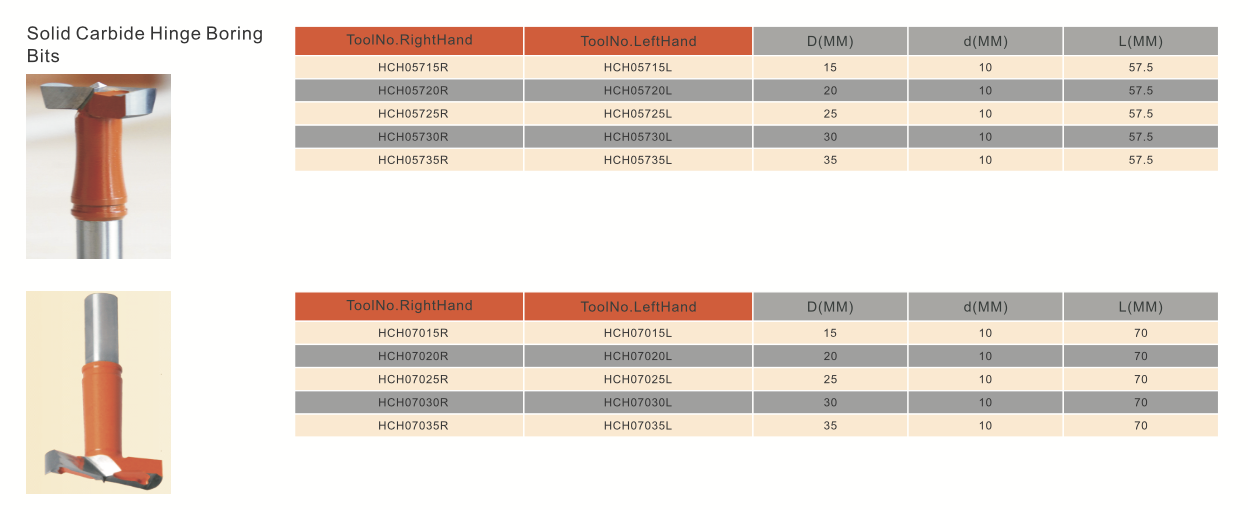

3.3 Hinge boring bits

3.4 Carbide router bits for solid wood, MDF, etc..

4: Problems and Solutions for problems often happened in the use of woodworking drill bits

4.1 Broken Edge while machining

Reason: (1) Score-edge is no longer sharp.

(2) Center location point and shank’s concentricity are over-proofed.

(3) CNC router machine’s rotation shaft pulse oversized.

(4) The clamps of shank is loose and not locked.

(5) The plank is moving while drilling under CNC router.

(6) Chief axis’s rotation speed can’t match to feeding speed of the woodworking drills.

4.2 The hole is ellipse after machined.

Reason: (1) Center location point of the dowel drills & through hole drills is no longer sharp.

(2) Plank is moving while machining

(3)Chief axis’s rotation speed cannot match feeding speed.

4.3 Plank’s hole is burned after machining.

Reason: (1) the spiral groove is blocked which leads to bad chip removal.

(2) Machined material like plywood, wood is not dry enough.

(3) Chief axis’ s rotation speed can not match the feeding speed of these dowel drills, or through hole drills.

Solution:Adjust the machine and cutting parameters, change for a new tools

Under normal circumstances, the wood drilling drills bits can work very well,but we should also need to do the best not to drill into the nail. Do not make the horizontal drill bit touch the vertical drill bit by mistake, otherwise the drill bit will be damaged. The 35mm hinge drill bit used for the door hinge needs to be refurbished usually. When buying drill bits, we suggest to buy high quality ones, so that the operation will be smooth, and the finished products will be good!

The air pressure is also very important, so does the feed speed. The speed of the dowel drill bit and through hole drills below 10mm/min can be faster, but the drill bit above 15mm/min must have a slower feed speed, otherwise it will easily burst! Attention should be paid to the selection of drill bits. Normal quality drills bits can be used for MDF in general, high quality and stable woodworking drill bits are strongly suggested for shaving board.

Post time: Sep-15-2020