5 most popular problems and solutions in using industrial circular carbide saw blades for wood cutting

Today we will share some of the problems encountered during carbide saw blades usage. What are the main reasons? How to deal with them?

The 1st Problem–Abnormal sound

The reasons are as below:

1. The alloy saw blade is overused, the temperature is too high, and the saw blade is deformed due to external force. At this time, correction is required and necessary.

2. There is gaps in the equipment spindle, runout and swing.

3. The circular carbide saw blade has something attached to it, and it touches objects outside the cutting material during cutting.

4. It is recommended to buy alloy saw blades with muffler wires to reduce noise.

5. Rotation speed does not match the cutting condition.

6. Irregular chip removal slot– check the slot and adjust its position.

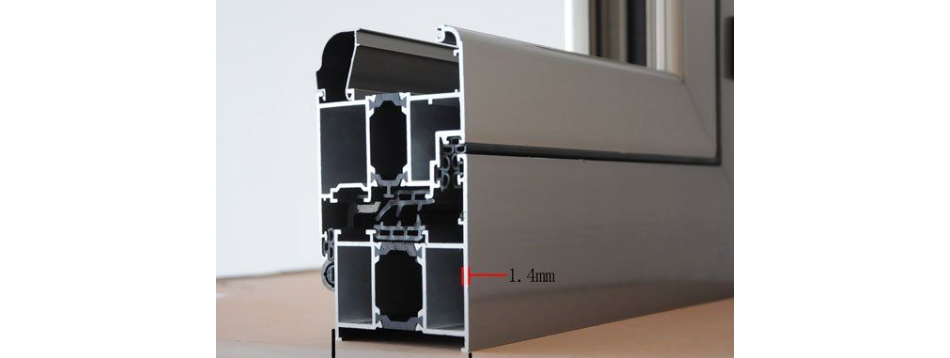

The 2nd problem-There are burrs or uneven surfaces on the workpiece

Solution: 1. Check the tilt of the circular saw blade, the uneven saw blade needs to be corrected

2. Saw blade saw tooth is defect and damaged or warn out

3. Adjust and correct the installation of the saw blade

4. Change the circular saw blade if the saw blade has been used for too long and the accuracy of the cutter head is not good enough for cutting.

5. Change another tooth style when you find the tooth profile is inappropriate or the number of teeth is small (BT teeth are commonly used for doors and windows)

6. Adjust the accuracy of the equipment spindle if it is not high precision enough.

7. Make sure the adequate lubrication.

The 3rd problem-Abnormal feeding

The main reasons are as below:

1. The alloy saw blade slips

2. The spindle is stuck by some objects.

3. There is a blocking at the discharge port.

The fourth problem-caught of carbide saw blades

The main reasons are as below:

1. The material of the saw blade is not suitable for the material being processed

2. The design of the carbide circular saw blade is unreasonable and the chips cannot be removed in time

3. Excessive use and high temperature of the saw blade during processing

4. The circular saw blade is caught or the machine spindle jumps or the saw blade is installed incorrectly

Please stop the machine in time if the above phenomenon occurs.

The 5th Problem-the carbide cutter head of the saw blades wears too fast

The reasons are: the angle of the cutting edge is unreasonable, some inferior blades have poor wear resistance, the saw blade is not perpendicular to the workpiece, and the saw blade speed is too high.

Solution: Check the flange of the spindle to ensure the verticality of the saw blade and the equipment, check the speed of the saw blade when it is working. Grind and maintain the saw blade in time. If the above cannot be solved, please try a new saw blade.

We hope and believe that the correct and high quality cemented carbide saw blades will improve product quality, shorten processing cycles, and reduce processing costs.

Post time: Sep-15-2020