In today's tool market, the perfect combination of woodworking turnover spiral cutter shafts, spiral cutter heads and indexable blades, coupled with imported European top equipment and excellent processing technology to produce perfect carbide turnover knives, is the theme of the future. Carbide turnover spiral blades have the advantages of being convertible, reducing costs, increasing efficiency, and ensuring the accuracy of the tool holder transfer and cutting life.

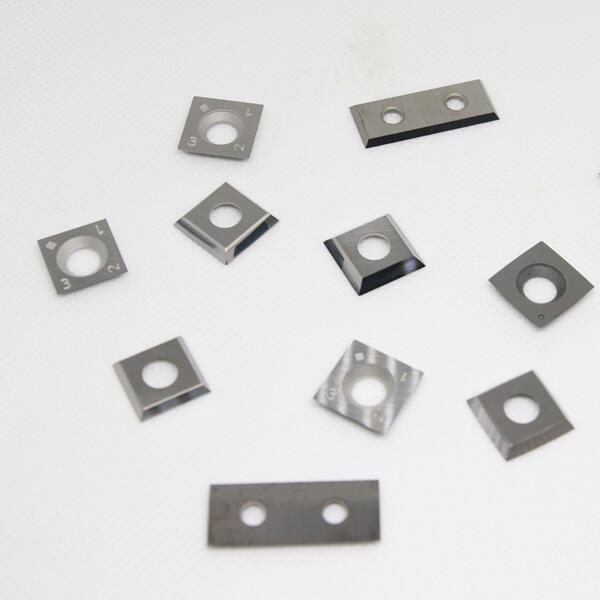

Reversible spiral blades have different names: such as turnover blades, indexable carbide inserts, reversible woodworking machine clamp blades. but they are all one thing, and they are mainly used in two places: One is on the spiral tool holder, which is widely used on the cutter head and the tool shaft; the other is on the clamping tool body or the tool of the machining center.

In terms of materials, there are several alloy grades. Due to the level of alloy material standards, there are different grades of quality, which are used in different wood..

Application: Recommended grade of carbide reversible blades and trunover blades for different materials

|

Grade |

HDF/MDF |

Chipboard |

Hard wood |

soft wood |

plywood |

|

HCK01 |

Excellent |

Excellent |

not suggested |

not suggested |

not suggested |

|

HCK10UF |

Excellent |

Excellent |

Excellent |

not suggested |

good |

|

HCK30UF |

Good |

Excellent |

Excellent |

Good |

Good |

|

YG6X |

not suggested |

Good |

Excellent |

Excellent |

Excellent |

Here below are the TOP 5 advantages of the carbide turnover blades

1. Reversible: The knife edge of one side is blunt or broken, you can change to another side and continue using it until several sides are used up and then change the blade for grinding.

The blade with 4 blades can be converted (can be used on 4 sides), the commonly used specifications are: 14x14x2, 15x15x2.5.

Two blades can be converted (can be used on two sides). Common specifications are: 20x12x1.5, 30x12x1.5, 40x12x1.5, 50x12x1.5, 60x12x1.5. Other non-standard can be customized.

2. Reduce the number of blade changes and directly improve efficiency and save time, minimize the processing cost.

3. Superfine alloy woodworking reversible knives are specially developed for various tool holder systems. The high-quality blades ensure the transfer accuracy and cutting life of the tool holders.

4. make the surface processing quality of the object smooth and perfect, no longer need to spend a lot of grinding and repairing.

5. It is very competitive. The ultra-fine particle alloy material makes the blade durable and sharp!

In addition, regarding the angle of the turnover knives, the angle of the matching blade on the cutter body is generally 30 degrees. Our turnover blades are generally customized according to the needs of users.

For wood with different hardness, the angle of the blade will be different. Take a 14x14x2 blade as an example. Normal medium softwood wood is recommended to use 35 degrees or 37 degrees; and super hard wood is recommended to use an angle of 30 degrees, so that the impact resistance is stronger and the tool can play a better effect.

We can manufacture various size carbide turnover blades and planner knives, welcome to send us drawing and your idea.

Post time: Nov-09-2020