4 cov lus qhia txog kev ua haujlwm tseem ceeb tshaj plaws ntawm cov khoom siv woodworking laum thiab cov kev cai tshwj xeeb tshaj plaws ntawm HW dowel xyaum thiab dhau los ntawm lub qhov taub & hinges cov khoom siv hauv cov cuab yeej kev ua lag luam woodworking.

1: Xaiv cov kev xyaum kom yog thiab ua kev tiv thaiv

1.1 Laum laum yog tsim los rau cov kws ua yeeb yaj kiab woodworking laum. Ua tib zoo saib cov kev taw qhia kev sib hloov ntawm laum me ntsis. Peb yuav tsum xaiv ib txoj kev taw qhia los ntawm sab tes xis lossis sab tes laug.

1.2 Peb yuav tsum zam kom tsis txhob txiav cov khoom siv tsis yog ntoo xws li hlau, xuab zeb thiab pob zeb.Because woodworking laum cov khoom siv tau txais cov txheej txheem thiab cov yas puab sab hauv rau ntau qhov sib txuas ntawm cov laug cam thiab cov ntoo zoo, tsis yog rau cov khoom siv nyuaj heev.

1.3 Siv cov kev cai ntev ntev kom ntau li ntau tau, thiab nias ntoo nruj nreem thaum lub sijhawm ua haujlwm kom tsis txhob muaj cov khoom lag luam uas tsis tsim nyog lossis tsis ua haujlwm ntawm cov khoom siv no rau cov dig muag lossis dhau ntawm lub qhov.

1.4 Nws tseem tsim nyog los siv lub tsho qauv. Kev hnav los yog nplaum rau sab hauv lub qhov yuav ua rau lub hauv paus tsis ruaj khov uas yuav ua rau lub laum ya tawm thiab tshee, ua rau cov khoom tsis muaj peev xwm.

1.5 Tshawb xyuas thiab xyuas kom tseeb tias cov hlau xaim yog cov av khov kho, txhua qhov yog qhov qub, txoj haujlwm ua haujlwm yog ci, (cov neeg ua haujlwm tsis siv lub tshuab ua haujlwm).

2. Hnav khaub ncaws nruj, duav thiab tes tsho nruj, tsis muaj txoj hlua khi, tsis rau cov hniav nyiaj hniav kub, tsis muaj hnab looj tes, xyuam xim tiv thaiv qhov muag.

2. Kev tu cov woodworking laum me ntsis

2.1. Thaum siv cov laum, tawm nws tawm hauv lub thawv thiab nruab nws mus rau hauv lub pluaj chle ntawm ntxaiv lossis cov cuab yeej cuab tam rau kev rho tawm kev hloov tawm. Muab rov qab tso rau hauv lub thawv tom qab siv tas.

2.2 Los ntsuas qhov taub ntawm txoj kev ua lag luam woodworking tho me ntsis, siv cov ntsuas tsis sib txuas xws li lub tshuab ntsuas tsom kwm kom tiv thaiv kev txiav los ntawm kev sib cuag nrog cov cuab yeej ntsuas kev ntsuas thiab raug mob.

2.3 Qee lub tshuab CNC router siv cov nplhaib sib dhos. Qee lub tshuab CNC drilling siv tsis siv lub nplhaib sib dhos. Yog hais tias txoj hauj lwm ntiv nplhaib siv, qhov tob thaum lub sij hawm teeb tsa yuav tsum yog. Yog hais tias muab tso rau lub nplhaib sib dhos tsis siv, lub elongation ntawm laum me ntsis ntawm qhov ntxaiv yuav tsum yog qhov tseeb. Txhawm rau kom ua kom zoo ib yam, ntau txoj kab txiav ntoo cav ntoo yuav tsum khaws tib lub qhov tob ntawm txhua qhov ntxaiv. Yog tias nws tsis raug xwm yeem, nws yuav ua rau lub ntsis ntsaum tuaj yeem ua rau lub rooj lossis ua tsis tau los ntawm lub phaj, uas ua rau cov khoom pov tseg thiab cov ntawv ntoo.

2.4. Nyob rau lub sijhawm zoo li no, siv 40 lub koob yees duab lub koob yees duab tuaj yeem siv los xyuas qhov hnav ntawm kev txiav ntawm cov nqaj hlau nqaj no thiab los ntawm lub qhov tawm laum nrog cov lus qhia carbide.

2.5. Txhua zaus yuav tsum xyuas lub siab ntawm lub chuck thiab lub zog ntawm lub chuck. Kev ua rau lub siab tsis zoo yuav ua rau lub taub me me ua kom lub ntsej muag tawg thiab apertures loj. Yog tias lub clamping quab yuam tsis zoo, qhov tseeb ceev yuav txawv ntawm lub txheej txheem ceev thiab qhov cuab yeej ua haujlwm woodworking ua haujlwm yuav plam los ntawm chucks.

2.6 Nco ntsoov xyuas tus ntxaiv presser ko taw. Lub chaw tiv tauj ntawm cov xovxwm ntsuas ko taw yuav tsum yog kab rov tav thiab ntsug mus rau lub ntsiab loj yam tsis muaj kev thaiv kom tsis txhob txhawm rau txhawm rau ua kom lub pob taws tawm ntawm qhov tawg thiab qhov tawm ntawm qhov drilling.

2.7 Txhawm rau kom ntseeg tau tias lub neej kev pabcuam ntawm koj lub laum woodworking thiab txo qhov tsis ua tiav, peb yuav tsum tau xyuas tas li seb cov roj nplua nyeem ntawm lub laum woodworking yog txaus lossis tsis. Yog tias muaj tsis txaus, thov sau nws sijhawm.

2.8 Thaum lub sijhawm saib xyuas cov khoom lag luam woodworking laum no, thov nco ntsoov txiav tawm lub tshuab hluav taws xob ua ntej kev debugging thiab tswj kom tsis txhob muaj xwm txheej. Txhua qhov cuam tshuam ntawm sawdust, plua plav, khib nyiab, thiab lwm yam ntawm lub laum woodworking yuav tsum tau muab tshem tawm txhua hnub. Kev saib xyuas txhua hnub yuav tsum tau them rau kev tshem tawm sawdust thiab hmoov av rau ntawm cov lus qhia ntawm cov lus qhia, lub rooj zaum zawv zawg thiab cov lus qhia ntawm lub thawv ntsug, thiab cov lus qhia yuav tsum tau muab ntxuav thiab ntub ua ntej txav txhua lub sijhawm. Tshawb xyuas cov roj theem ntawm ob ntu txhua hnub.

2.9 Txheeb xyuas seb lub tshuab cua nrawm nrawm raws li tus qauv, kev kub siab ib txwm yog 0.5-0.8mpa; kuaj xyuas seb cov dej nyob hauv lim hauv ob qho kev sib koom ua ke puas lawm los yog tsis. Kuaj seb lub tshuab hluav taws xob hloov hluav taws xob siab ntawm lub twj paj nruag dowel hnyiab thiab dhau los ntawm lub qhov tso tawm yog nyob rau hauv tus nqi uas tau teev tseg, thov tseem kuaj seb puas muaj kev lim cua hauv qhov sib koom ua ke ntawm cov pa hluav taws xob thiab ntsuas kev tsim nyog.

3: 4 hom nrov tshaj plaws ntawm cov laum me ntsis rau ntoo thiab CNC router tshuab

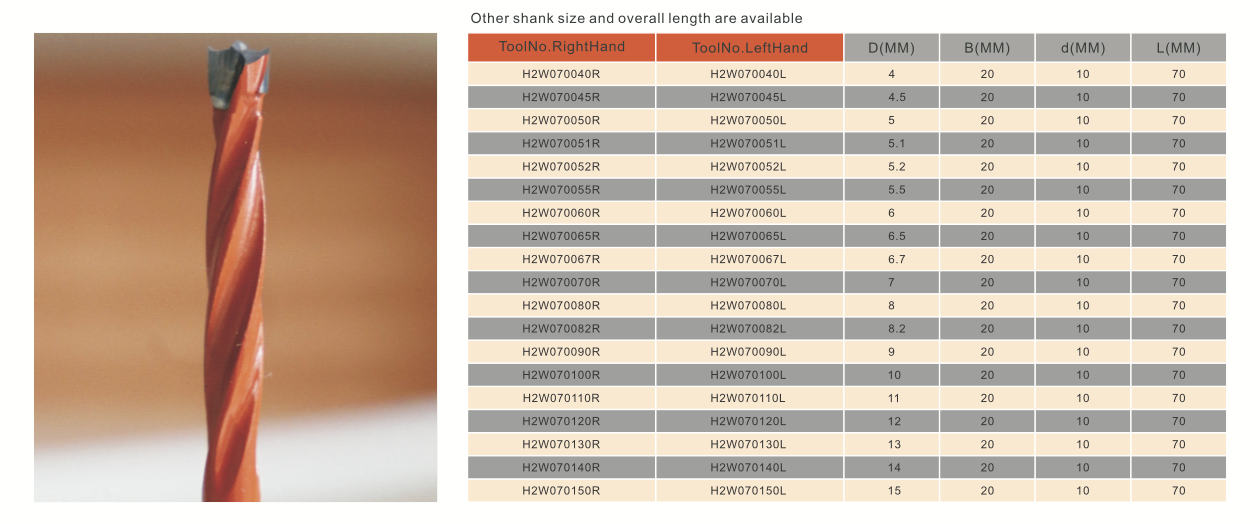

3.1 HW Brad taw qhia cov kab tho txawv (dowel xyaum) nrog rau cov khoom ntoo, MDF ntoo-Vaj Huam Sib Luag, cov ntoo ntoo, cov ntawv yas thiab laminated.

3.2 HW Los ntawm qhov tho qhov rau cov khoom ntoo, MDF, thiab lwm yam.

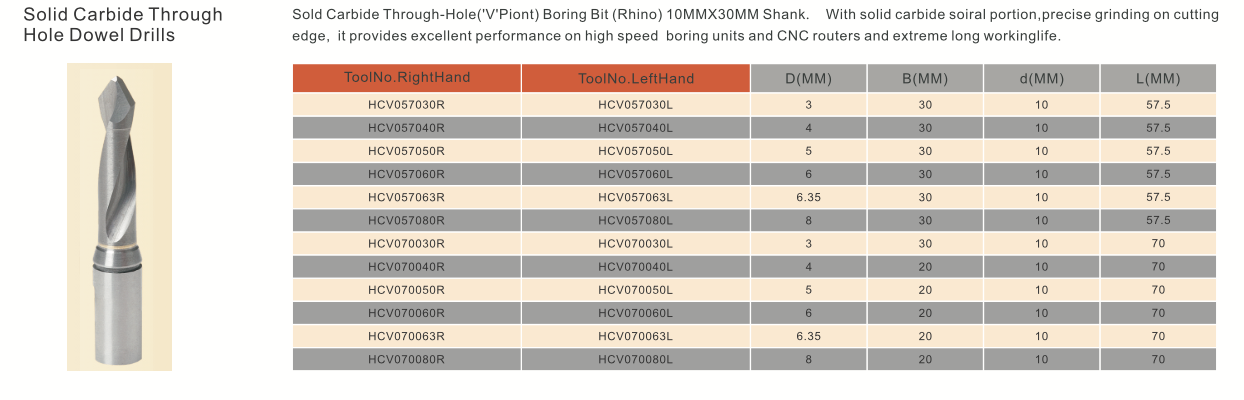

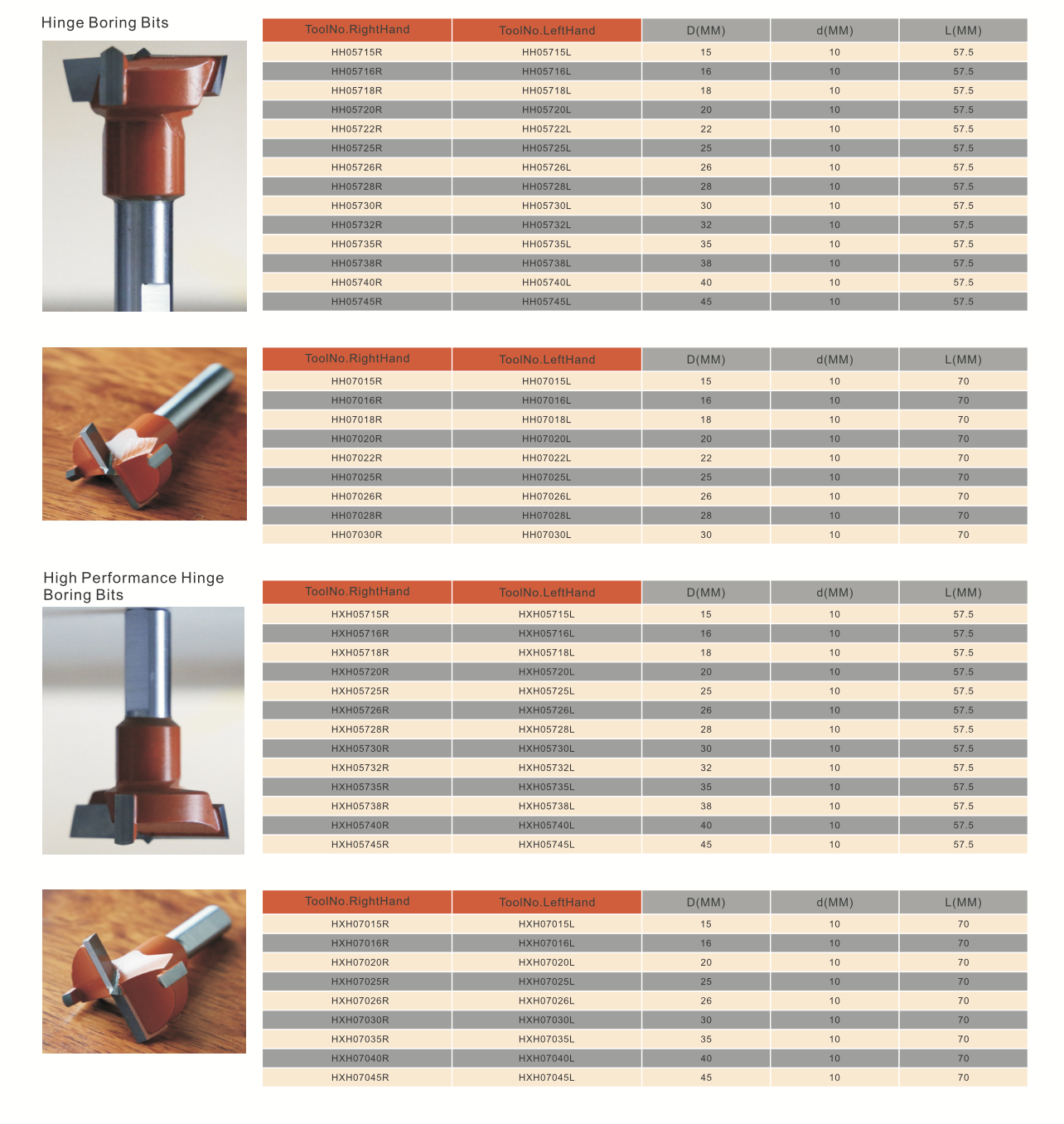

3.3 Pob khawm tho txawv

3.4 Carbide router khoom rau cov khoom ntoo, MDF, thiab lwm yam.

4: Qhov teeb meem thiab kev daws teeb meem rau cov teeb meem feem ntau tshwm sim hauv kev siv cov khoom siv woodworking laum

4.1 Lub Tawg Ntawm Ntug thaum lub sijhawm machining

Qhov laj thawj: (1) Score-ntug tsis muaj qhov ntse dua.

(2) Qhov chaw nyob nruab nrab taw tes thiab shank lub concentricity dhau-pov thawj.

(3) CNC router tshuab kev sib hloov ncej pulse oversized.

(4) Cov clamps ntawm shank yog xoob thiab tsis xauv.

(5) Lub plank yog txav thaum lub cav drilling hauv CNC router.

(6) Chief axis txoj kev sib hloov ceev tsis tuaj yeem sib piv rau qhov kev pub noj nrawm ntawm cov chav xyaum ua haujlwm.

4.2 Lub qhov yog ellipse tom qab machined.

Vim li cas: (1) Qhov chaw nyob ntawm qhov taw tes ntawm lub suab seev tho & ntawm lub qhov taub yog tsis muaj ntse.

(2) Plank yog txav thaum lub tshuab

(3) Chief axis txoj kev sib hloov ceev tsis tuaj yeem sib phim qhov noj ceev.

4.3 Plank lub qhov yog hlawv tom qab machining.

Vim li cas: (1) cov kauv kiav sib tsoo yog qhov thaiv uas ua rau cov nti tawm tsis zoo.

(2) Cov khoom mached zoo li plywood, ntoo tsis qhuav txaus.

(3) Chief axis's txoj kev sib hloov ceev tsis tuaj yeem sib piv nrog qhov pub mis ceev ntawm cov tshuab duav, lossis los ntawm kev xyaum.

Kev daws : kho lub tshuab thiab txiav tsis tawm, hloov rau qhov tshiab

Nyob rau hauv ib txwm muaj xwm txheej, cov ntoo tho lub qhov cub tuaj yeem tuaj yeem ua haujlwm zoo heev, tab sis peb kuj yuav tsum tau ua qhov zoo tshaj plaws kom tsis txhob tho tawm rau hauv cov ntsia hlau. Tsis txhob ua rau txoj kab tav toj tav toj kov txoj kab ntsug txoj cai me ntsis los ntawm qhov yuam kev, txwv tsis pub lub laum yuav raug puas ntsoog. Lub 35 hli pob khawm laum me ntsis siv rau lub qhov rooj pob khawm yuav tsum tau kho kom zoo dua qub feem ntau. Thaum muas cov laum laum, peb xav kom yuav cov khoom lag luam zoo, kom kev ua haujlwm tau zoo, thiab cov khoom tiav yuav zoo!

Cov cua ntsig cua kuj tseem ceeb heev, yog li qhov kev pub ceev. Kev nrawm ntawm lub twj tso kua mis ntawm lub twj tso tawm qis thiab dhau los ntawm qhov kev xyaum hauv qab 10mm / min tuaj yeem nrawm dua, tab sis cov laum tawm saum 15mm / min yuav tsum muaj qeeb qeeb noj, txwv tsis pub nws yuav yooj yim tawg! Xim yuav tsum tau them rau kev xaiv ntawm cov laum me me. Cov laum zoo ua haujlwm yuav siv tau rau MDF feem ntau, cov khoom lag luam zoo thiab ruaj khov woodill laum cov kev xav tau pom zoo rau shaving board.

Lub sijhawm tshaj tawm: Sep-15-2020